Hi everyone, I would like to share some notes and questions I made during a HAZOP (Hazard Operability) safety study for an oil water separation system typical for an offshore oil and gas facility.

Like my other posts, questions here can be asked for any generic relavant process plants.

Please comment, like and subscribe.

|

| Photograph 1: Generic Offshore plant with Oil Water Seperator (somewhere) |

Oil water separator vessel system:

1. Can you design the vessel to withstand vacuum (costly) rather than have a vacuum relief valve on the system?

BUT - This relief valve could allow air into system and create flammable atmospheres (dangerous)

2. Is a high interface level alarm needed?

(1) Can excess water damage the catalyst?

(2) An automated controller to remove water from the interface level is not recommended – because if it fails then oil will overflow into the drain system

3. Can a pump's suction line in the tank base be elevated to account for incomplete oil water separation?

4. Can the heat exchangers be designed to withstand maximum pressure for all but fire conditions – Therefore avoid need for a pressure relief valve system?

|

| Figure 2: Flow diagram of an oil water seperator |

Transfer Pumps:

5. Are bypass lines locked off?

(1) BUT this is harder to reopen quickly if control valve shuts

(2) Do you need a bypass? How often does it fail shut?

(3) Can you use a flow controller valve rather than a restriction plate? – this will save power costs?

6. Should power supplies be duplicated?

7. Is there automatic start for spare pumps?

8.

Is there voltage protection for the equipment? –

this must be kept online or be able to restart quickly on demand

9.

Do control valves fail open or stay put?

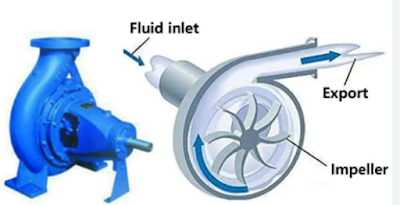

Figure 3: Typical centrifugal pump

Water Drain System:

1. Can water sump and drain freeze up? If so has it been lagged (insulated) or heat traced?

2. If alternative cooling water used, does grade of steel need to be upgraded to account for corrosion?

3. Is there consequence of adding more water? e.g. Corrosion, leaking valve, accumulation in dead ends, etc.

Pipework:

10. Is a low flow alarm better than a vessel low level alarm in downstream vessel?

1) It is better to measure directly

2) BUT low-level alarm is cheaper

3) Similar example: a pump recirculation line can be cheaper than a high temperature trip instrument – it needs less maintenance

11. Is thermal expansion possible due to fire or strong sunlight? Does the pipework section need thermal relief valve?

Figure 4: Generic pipework in the sun

12. Are there enough low point drains and nitrogen purge points on the line?

13. Are the gaskets used spiral wound? Has the number used kept to a minimum?

14. Are nuts and bolts kept to a minimum?

15. Are valves with rising spindle used? Thus can be seen by an operator

16. Are spectacle plates installed where regular blinding of joints? This is for maintenance and prevent contamination

Thank you for reading, please comment, like and subscribe to this blog

Hope you have enjoyed reading this

Chiraq